The Future of Plastics

Our Mission is to reduce plastic waste, mitigate global dependence on hydrocarbons and build a robust and sustainable supply chain through the development and commercialization of a series of bioplastic resins specifically formulated to mimic the structural properties of traditional plastics."The future of plastic is to promote reusability and diminish our reliance on hydrocarbons manufactured with harmful additives. We believe the immediate "Single Use Plastics Ban" is only the start of an era of revolution within our manufacturing industry. At the Green Future Growth Company, we are exploring a wide range of applications using waste byproducts to help develop eco-friendly bioplastics suitable for end consumer products ready for commercialization.“

Our Products

No hydrocarbons are used in our resins or in the development of our resins.Our biopolymers are derived from vegetable oil, sugar, corn starch, wood flour and will biodegrade in 90-180 days, with some products able to biodegrade in 30 days when exposed to the natural enzymes present in soil and/or an oceanic environment. At end of life material can be ground up and used as fertilizer.Finished manufactuered products are meant to be reusable - ongoing testing and validation in adherence to the plastics regulation and customer use cases.

Agricultural Product Resin

Biodegradable resin converted from agricultural waste/byproduct. Can develop simple injection mold, vacuum form and extruded film products – in agricultural and food packaging spaces.Materials are compostable (other biodegradability tests per soil and oceanic environment)

GreenMold

Adaptable manufacturing process: Injection MoldingProducts such as – disposable items used in office, food & beverage and electronic parts etc..

Good stiffness, toughness and processing properties, temperature-resistance and water-proof, ideal printing properties

GreenWrap

Adaptable manufacturing process: Film ExtrusionProducts such as – tape casting, garbage bags, compositing bags, packaging film, food packaging, disposable gloves etc..

Good processibility, transparency, barrier properties, heat-sealing and printing properties

GreenForm

Adaptable manufacturing process: Thermoforming & multilayered compounding to sheetProducts such as - clamshell food box, cold & hot beverage cup, packing sheet, etc..

Good physical synthesis performance, barrier properties and easy printing, good heat resistance and toughness

GreenBlow

Adaptable manufacturing process: Blown film extrusionProducts such as - cosmetic bottles, shampoo bottles, soft molded products etc..

Good toughness and tensile strength, barrier properties, glossiness, solvent-resistance, painting & printing, chemical stability

Manufacturing Specifications

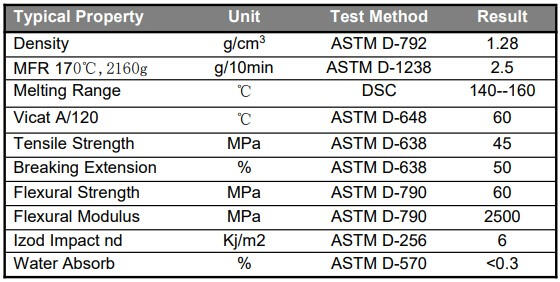

GreenMold (Injection Mold)

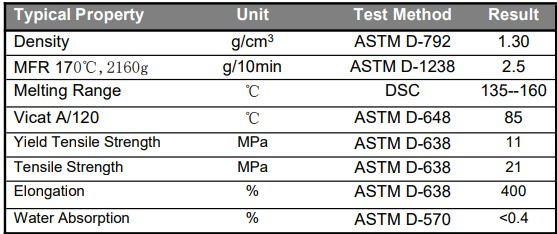

GreenWrap (Film Extrusion)

Manufacturing work instruction and MSDS (safety) available at customer request. Material resin adapted to conventional manufacturing process.

Contact Us

The future is green! Contact us today.

GreenMold

GreenMold